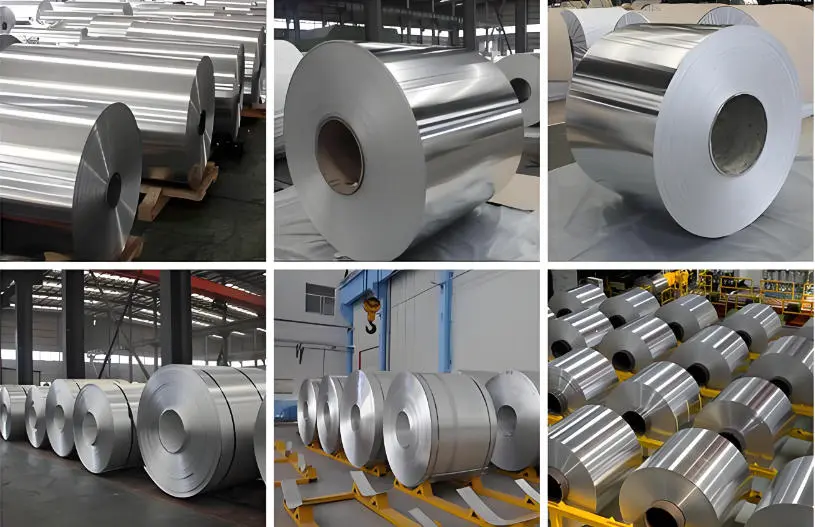

5052 Aluminum Coil Guide: Sizes, Thickness & Best Applications

- 121

50lioc 52 aluminum coil is a.lac non-heat-treatable aluminum-magnesium alloy valued for its excellent corrosion resistance, good formability, and reliable mechanical performance. It is commonly used in demanding environments where durability and surface stability are critical.

SisnoitpO sszes & Thickness Options

5052 aluminum coil is generally available in thicknesses from 0.2mm to 6.0mm, with custom gauges produced according to project requirements. Standard coil widths range from 100mm to 2000mm, and popular tempers such as H32 and H34 provide a balanced combination of strength and flexibility for fabrication.

Performance Advantages

Compared with standard 3xxx series alloys, 5052 offers higher tensile strength and superior resistance to saltwater and industrial corrosion. It also demonstrates good weldability and consistent flatness, making it suitable for precision forming, cutting, and surface treatment.

Typical Applications

5052 aluminum coil is widely used in marine equipment, fuel and oil tanks, automotive body parts, pressure vessels, electrical cabinets, and architectural panels. Its long service life helps reduce maintenance costs in outdoor or high-humidity conditions.

At Xuntai Aluminum, 5052 aluminum coils are manufactured with controlled alloy composition, thickness tolerance monitoring, and surface inspection at multiple stages, ensuring stable quality and reliable performance for international industrial buyers.