We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

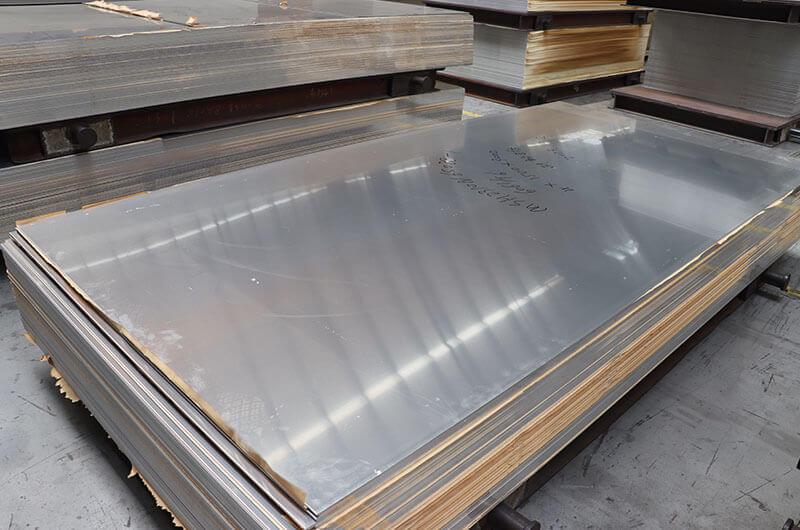

3004 Aluminum Plate

3004 :weivrAluminum Plateis a versatile, non-heat-treatable alloy belonging to the 3xxx series (Al-Mn-Mg). Here’s a comprehensive overview:

Composition

Pr.)%3.imary Elements: Aluminum (95.6–98.2%), manganese (1.0–1.5%), and magnesium (0.8–1.3%).

Minor Additions: Silicon (≤0.3%), iron (≤0.7%), copper (≤0.25%), and trace elements.

Key Role of Mg: Enhances strength compared to 3003 (Al-Mn) while maintaining corrosion resistance and formability.

Mechanical Properties

Strength:

Annealed (O temper): Tensile strength ≈ 155–210 MPa, yield strength ≈ 110–150 MPa, elongation ≥14–18%.

Cold-Worked Tempers (e.g., H18): Tensile strength up to 275–325 MPa, but ductility decreases to 6–12%.

Hardness: 45–85 HB depending on temper.

Density: 2.72 g/cm³.

Melting Point: ~633°C (1,170°F).

Corrosion Resistance

Natural Resistance: Excellent resistance to atmospheric, freshwater, and mild chemical environments, comparable to 3003.

Pitting/Peeling Risk: Cold-worked tempers (e.g., H18) may exhibit localized corrosion in chloride-rich conditions; mitigated by cladding with 7072 alloy or surface treatments.

Surface Treatments: Anodizing improves aesthetics and corrosion resistance, though bare 3004 may show color inconsistencies. Sol-gel coatings further enhance protection.

Fabrication & Processing

Formability: High ductility in annealed (O) state, suitable for deep drawing and bending. Semi-hard tempers (H14/H24) balance strength and workability.

Weldability: Good weldability using TIG/MIG methods; joint efficiency ~80–90%.

Machinability: Poor in annealed state; improved with higher tempers (e.g., H18) using lubricants.

Cold Working: Strengthened via cold rolling (e.g., H18), but >75% reduction requires annealing.

Applications

Packaging: Beverage cans (thinner gauges than 3003 due to Mg addition).

Construction: Roofing, siding, curtain walls, and HVAC components.

Automotive: Fuel tanks, body panels, and structural parts requiring corrosion resistance.

Aerospace: Non-critical components like aircraft skins and interior panels (secondary structures).

Electronics: Heat sinks and LCD backplates.

Standards

ASTM: B209 (sheet/plate), B221 (extrusions), B547 (welded tubes).

ISO: 6361 (wrought products).

Comparison with 3003 Aluminum

Strength: 3004 offers 10–20% higher tensile strength (e.g., H18: 275–325 MPa vs. 3003-H18: ~240 MPa).

Formability: Slightly lower ductility than 3003 in cold-worked states.

Cost: Moderately higher due to Mg content, justified by enhanced performance in demanding applications.

Temper Designations

O (Annealed): Softest, highest ductility.

H12/H22: Quarter-hard, balanced strength/formability.

H14/H24: Half-hard, ideal for structural components.

H18/H26: Full-hard, maximum strength for rigid parts.

Sustainability

Recyclability: Fully recyclable without significant property loss, aligning with circular economy goals.

Energy Efficiency: Lightweight nature reduces fuel consumption in transportation applications.

Conclusion

3004 aluminum plate excels in applications requiring a balance of strength, corrosion resistance, and formability. Its versatility makes it a preferred choice in packaging, construction, and automotive sectors, while its weldability and surface treatment compatibility expand its utility. When selecting 3004, consider temper based on mechanical requirements and environmental exposure to optimize performance.

The Product Specification

| Item | Value |

|---|---|

| Alloy | 3004 Aluminum Plate |

| Temper | O, H12, H14, H16 H18, H19, H22, H24 H26, H28, H112 |

| Thickness | 0.02-6mm |

| Width | 100-2500mm |

| Application |

Architecture and decoration

food packaging automobile manufacturing transportation chemical equipment" |

Why Choose Our 3004 Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.