We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

5052 Aluminum Plate

5052 aluminum plate is a versatile Al-Mg alloyrenowned for its exceptional corrosion resistance, formability, and weldability, making it a preferred choice in industries ranging from aerospace to automotive and marine applications. Here's a detailed breakdown of its key characteristics and applications:

1. Composition

Primary Alloying Elements:

Magnesium (Mg): 2.2–2.8% (primary strengthener, enhances toughness and corrosion resistance).

Chromium (Cr): 0.15–0.35% (improves resistance to stress corrosion cracking).

Impurities: Silicon (≤0.25%), Iron (≤0.4%), Copper (≤0.1%), and Manganese (≤0.1%).

Density: 2.72 g/cm³ (consistent with most sources, though some references cite 2.68 g/cm³ due to minor variations in alloy composition).

2. Mechanical Properties

Tensile Strength:

O (Annealed): 170–215 MPa

H32 (Strain Hardened + Stabilized): 210–270 MPa

H34 (Higher Strain Hardening): 230–290 MPa

Yield Strength:

H32: 160–215 MPa

H34: 185–240 MPa

Elongation:

O: 20–25%

H32: 12–20%

H34: 8–15%

Hardness:

H32: 150–180 HV

H34: 180–210 HV

Elastic Modulus: 69–70.7 GPa.

3. Key Advantages

Corrosion Resistance:

Excellent in marine environments and against salt spray (500+ hours without pitting per ASTM B117).

Welded joints retain high corrosion resistance compared to other alloys like 6061.

Formability:

High ductility allows deep drawing, bending, and cold rolling (up to 85% reduction).

Bending Radius: 0.5T (O ) to 1.2T (H32).

Weldability:

Suitable for gas metal arc welding (GMAW) and tungsten inert gas (TIG) welding, with reaching 90–95% of the base metal.

Argon-helium mixed gas (Ar+25%He) is recommended to reduce cracking risks.

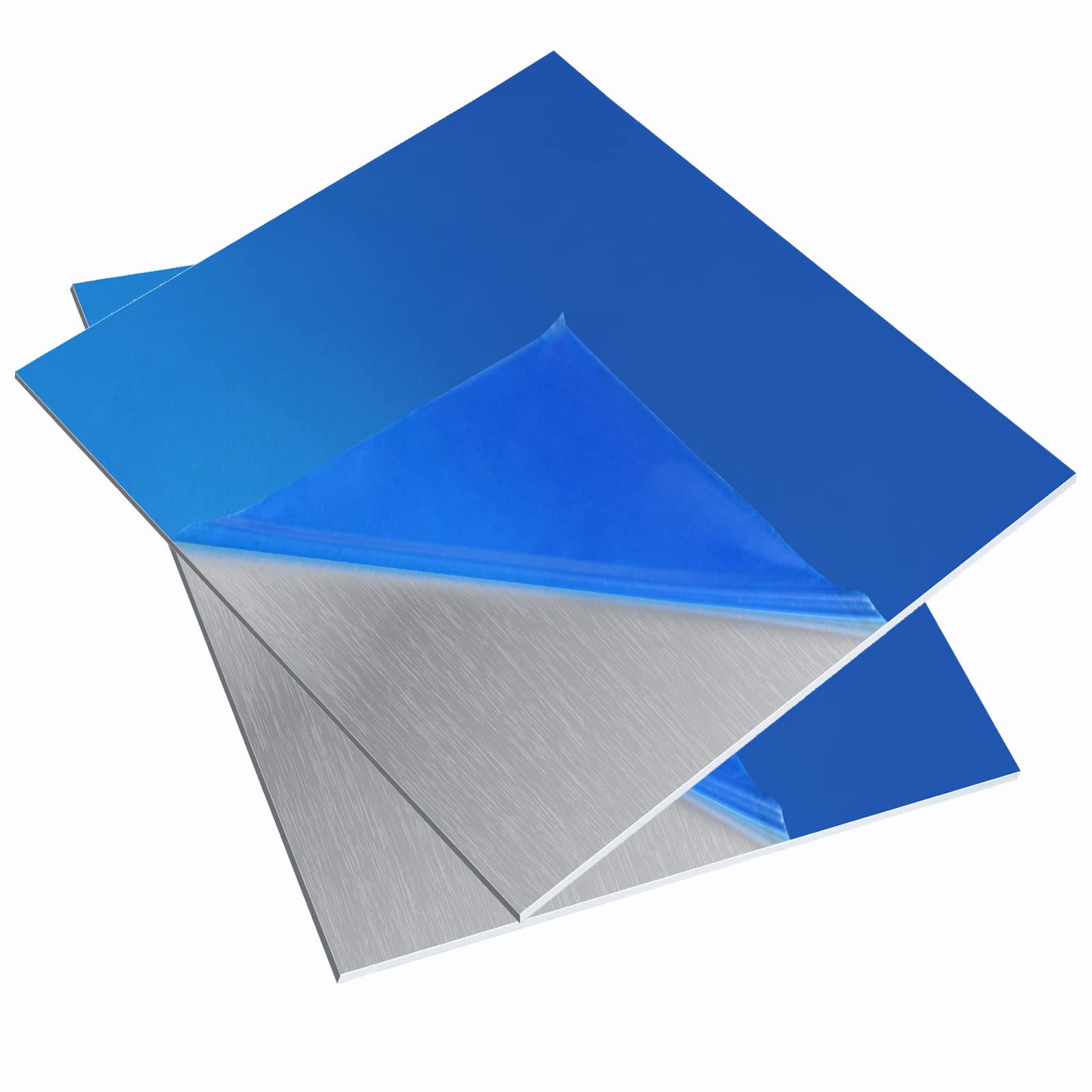

Surface Finish:

Ideal for anodizing (Type II, 15–25 μm film thickness) and powder coating, enhancing aesthetics and durability.

4. Applications

Aerospace:

Aircraft fuel tanks, fuselage panels, and structural components requiring lightweight and corrosion resistance.

Automotive:

Body panels, fuel tanks, radiator cores, and interior components (e.g., dashboard frames).

Marine:

Boat hulls, decking, and offshore equipment due to its resistance to saltwater corrosion.

Industrial & Construction:

Chemical storage tanks, high-pressure switchgear shells, and architectural curtain walls.

Consumer Goods:

Trolley cases, electronic device housings (e.g., laptops), and kitchenware.

5. Heat Treatment & Tempering

Annealing:

Conducted at 345°C to restore ductility after cold working.

Cold Working (H32/H34):

H32: 20–30% cold reduction + partial annealing to balance strength and formability.

H34: 30–40% cold reduction for higher strength but lower ductility.

Stress Relief:

Heating to 260°C for materials with ≥70% cold work to eliminate internal stresses.

6. Processing Considerations

Machining:

Annealed (O) material has poor machinability, but cold-worked states (H32/H34) improve chip control.

Warpage:

Minimize by using proper clamping and post-weld stress relief.

Cost:

Generally cheaper than 6061 but more expensive than 3003 aluminum, reflecting its balanced performance.

7. Standards & Specifications

ASTM: A952/A952M (sheet and plate), A902/A902M (general requirements).

AMS: AMS 4015, AMS 4016, AMS 4017 (aerospace applications).

ISO: ISO 6362-1 (aluminum and aluminum alloys for structural applications).

8. Comparison with Other Alloys

| Property | 5052 (Al-Mg) | 6061 (Al-Mg-Si) | 3003 (Al-Mn) |

|---|---|---|---|

| Strength | Moderate (H34: ~290 MPa) | High (T6: ~310 MPa) | Low (H14: ~160 MPa) |

| Corrosion Resistance | Excellent (marine-grade) | Good (requires post-weld treatment) | Good (general purpose) |

| Formability | Exceptional | Moderate | Good |

| Weldability | Excellent | Good | Fair |

| Typical Uses | Fuel tanks, marine parts | Structural components, automotive frames | Food containers, roofing |

9. Supplier Recommendations

Mingtai Aluminum: Offers ultra-wide (up to 2650 mm) and thick (up to 600 mm) 5052 plates with competitive pricing.

Chalco: Specializes in aerospace-grade 5052 sheets meeting AMS and QQ-A-250/8 standards.

10. Handling & Storage

Surface Protection: Use polyethylene film to prevent scratches and oxidation during transit.

Environmental Control: Store in dry, ventilated areas to avoid moisture-induced corrosion.

By leveraging its unique combination of corrosion resistance, formability, and weldability, 5052 aluminum plate remains a cornerstone material in modern manufacturing, balancing performance and cost-effectiveness across diverse industries.

The Product Specification

| Item | Value |

|---|---|

| Alloy | 5052 Aluminum Plate |

| Temper | O, H22, H24, H32, H34, H28, H38 |

| Thickness | 0.5–150mm |

| Width | 100-2500mm |

| Application |

Marine structures and shipbuilding

Automotive body panels and fuel tanks Aircraft fuel tanks and components Pressure vessels Building and construction materials Refrigeration units Kitchen utensils and cookware Signage and billboards Electronic enclosures" |

Why Choose Our 5052 Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.