Products Center

CC 1050 Aluminum Coil

1050 aluminum coil is with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity……[Read More]

CC 1060 Aluminum Coil

The 1060 aluminum shee thas good elongation and tensile strength, making it suitable for regular processing requirements (stamping, stretching), and it has high formability.……[Read More]

CC 1100 Aluminum Coil

1100 aluminum, known as commercially pure aluminum, is the softest aluminum available. It has an excellent host of benefits and is a good use for many applications spanning several industries.……[Read More]

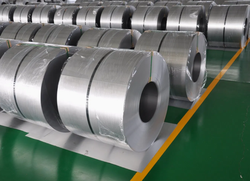

DC 1050 Aluminum Coil

DC 1050 aluminum coil is a pure aluminum sheet material, with an aluminum content of ≥ 99.5%. It possesses excellent ductility, corrosion resistance and electrical conductivity.……[Read More]

DC 1060 Aluminum Coil

DC 1060 Aluminum Coil is a pure aluminum coil, belonging to the 1000 series of aluminum alloys, with an aluminum content of over 99.6%. It is characterized by its high purity, and is produced by melting aluminum ingots and adding alloy materials. It is processed through cold rolling (DC) or hot rolling methods, followed by annealing, bending, cutting, and winding processes. This material exhibits excellent electrical conductivity (with a conductivity of approximately 61% IACS), thermal conductivity (with a thermal conductivity of 230 W/(m·K)), corrosion resistance (with a neutral salt spray test duration of over 1000 hours), and good processing properties. It supports various forming methods such as stamping, stretching, and bending. The surface is usually the rolled original color (Mill Finish), and is widely used in the fields of construction, electronics, and automobiles.……[Read More]

DC 1100 Aluminum Coil

1100 aluminum coil is pure aluminum, with excellent forming characteristics. 1100 is a typical industrial pure aluminum (99.00% of aluminum), and cannot be heat treated. The 1100 aluminum coils are sensitive to high temperatures ranging between 200 and 250°C, but the strength of the coils can be increased at subzero temperatures. CHAL will supply superior quality 1100 aluminum coil at, a reasonable price with ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008 standard guaranteed.……[Read More]

1050 H14 Aluminum Coil | Thickness, Properties & Applications

Buy high-quality 1050 H14 aluminum coil with excellent formability and conductivity. Available in custom thickness and width. Supplier of pure aluminum coil for industrial applications.……[Read More]