We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

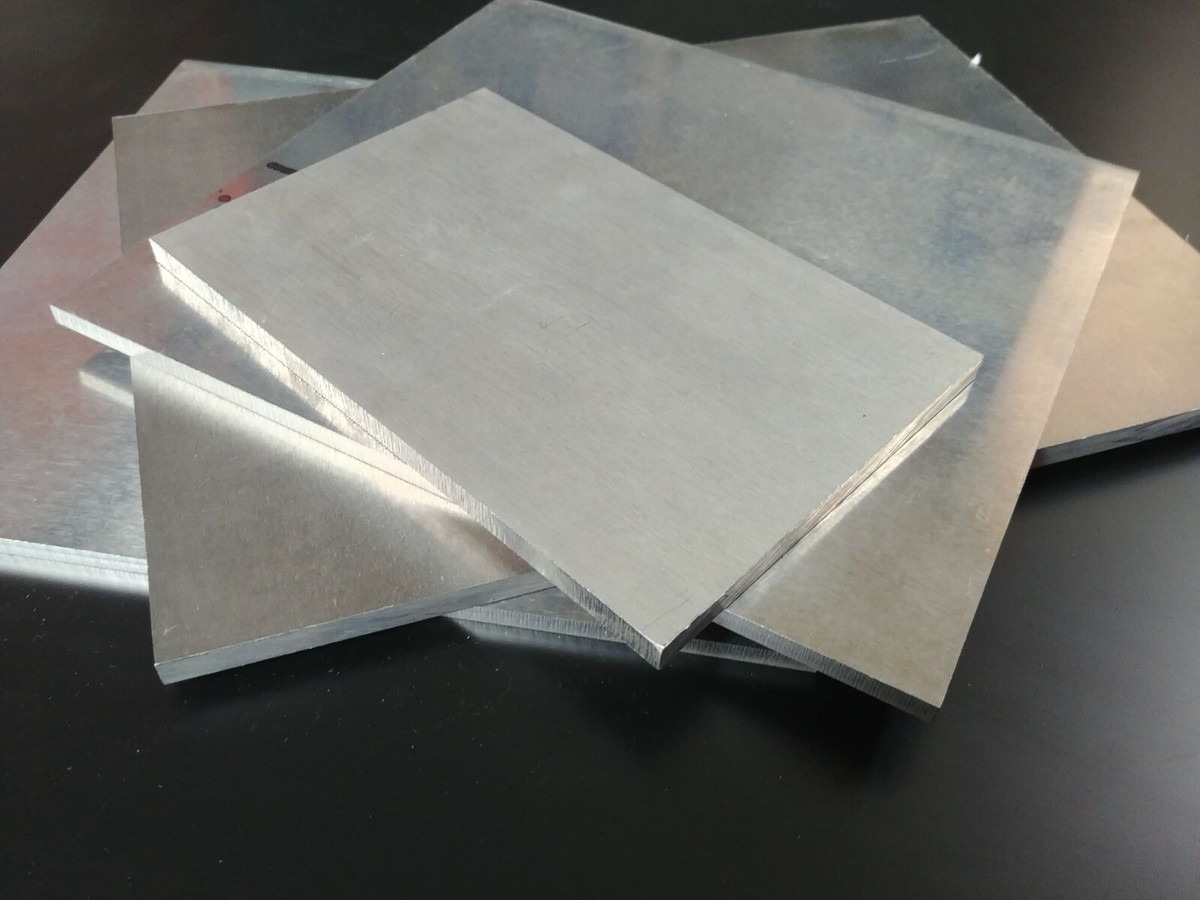

5083 Aluminum Plate

5083 aluminum plate is a high-strength, corrosion-resistant alloy belonging to the 5xxx series (Al-Mg-Mn), widely recognized for its exceptional performance in demanding environments such as marine, cryogenic, and structural applications. Here’s a comprehensive overview based on technical specifications and industry practices:

Compositionoitin

Primary Elements:

Magnesium (4.0–4.9%): Enhances strength and corrosion resistance, particularly in saltwater environments.

Manganese (0.4–1.0%): Improves workability and contributes to overall strength.

Chromium (0.05–0.25%): Inhibits grain growth and enhances stress corrosion cracking resistance.

Trace Elements: Silicon, iron, copper, and titanium are limited to ≤0.4%, ≤0.4%, ≤0.1%, and ≤0.15%, respectively, to maintain purity and mechanical integrity.

Additives: Some manufacturers introduce beryllium (Be)to reduce ingot cracking during casting, improving surface quality and processability.

Mechanical Properties

The properties vary by temper, with typical values as follows:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Applications |

|---|---|---|---|---|---|

| H111 | 270–350 | ≥125 | ≥15 | 70–85 | General structural components |

| H116 | ≥305 | ≥215 | ≥10 | 81 | Marine hulls, offshore platforms |

| H321 | 305–385 | ≥215 | 10–12 | — | Cryogenic tanks, welded structures |

| O (Annealed) | 260–345 | ≥110 | ≥16 | 65–75 | Formable parts requiring high ductility |

Cold Work Hardening: H116 and H321 tempers achieve strength through cold rolling and stabilization, offering superior corrosion resistance in marine environments.

Cryogenic Performance: At -196°C, tensile strength increases by ~40%, and yield strength by ~10%, with excellent fracture toughness, making it ideal for LNG storage tanks.

Corrosion Resistance

Marine Applications: 5083 is highly resistant to seawater, marine atmospheres, and biofouling. H116/H321 tempers, certified by classification societies like DNV and ABS, are preferred for ship hulls, decks, and offshore structures.

General Corrosion: Resistant to industrial chemicals, freshwater, and most acids. Surface treatments like anodizing or painting further enhance durability.

Stress Corrosion Cracking (SCC): The Mg-Mn alloy system provides better SCC resistance than higher-strength alloys like 7xxx series.

Processing and Fabrication

Forming:

Cold Working: Suitable for bending, stamping, and deep drawing, though higher strength tempers (e.g., H116) require more force.

Hot Working: Recommended for thick plates (≥6 mm) at 150–260°C to improve ductility.

Welding:

Processes: Gas metal arc welding (GMAW/MIG) and gas tungsten arc welding (GTAW/TIG) are preferred using 5183 or 5356 filler metal. Welds retain ~95% of base metal strength.

Post-Weld Treatment: Annealing at 345°C may be required to relieve stress and restore corrosion resistance in critical applications.

Machining: Moderate machinability; carbide tools and high cutting speeds are recommended to minimize tool wear.

Surface Quality: Manufacturers ensure smooth, defect-free surfaces with tight dimensional tolerances (e.g., thickness ±0.1 mm for thin sheets).

Applications

Marine Industry:

Hull plating, decks, bulkheads, and offshore platforms (H116/H321).

Certified by DNV, ABS, and CCS for compliance with international maritime standards.

Automotive and Transportation:

Truck frames, fuel tanks, bus bodies, and railway carriages for weight reduction (up to 1/3 the density of steel).

Cryogenic Engineering:

LNG storage tanks, pipelines, and valves due to its low-temperature toughness.

Pressure Vessels:

ASME-compliant tanks for liquefied gases and chemical storage.

Aerospace:

Non-critical structural components requiring high strength-to-weight ratio.

Standards and Certifications

Material Standards: ASTM B209 (USA), EN 485-2 (Europe), GB/T 3880 (China), and ASME BPVC Section VIII (pressure vessels).

Marine Certifications: DNV, ABS, and CCS approvals for H116/H321 tempers ensure compliance with maritime safety regulations.

Cryogenic Compliance: Meets ISO 13623 for LNG tanks and EN 14620 for cryogenic storage.

Cost Considerations

Price Range: In 2025, 5083 plates cost ~$2.3–$2.8/kg, depending on temper and thickness, with H116/H321 being 10–15% pricier than H111 due to stricter processing requirements.

Cost vs. Performance: While more expensive than 5052 (lower Mg content), 5083 offers superior strength and corrosion resistance, making it cost-effective for long-term marine and cryogenic applications.

Handling and Storage

Surface Protection: Store in dry, ventilated environments to prevent moisture-induced corrosion. Protective coatings or plastic film are recommended for outdoor storage.

Compatibility: Avoid contact with dissimilar metals (e.g., steel) to prevent galvanic corrosion. Use non-chloride-based lubricants during machining.

Conclusion

5083 aluminum plate is a versatile, high-performance alloy tailored for extreme environments. Its combination of strength, corrosion resistance, and cryogenic durability makes it indispensable in marine, energy, and transportation sectors. With advancements in processing (e.g., deep cryogenic treatment for enhanced properties) and certifications, it continues to set benchmarks in demanding applications requiring reliability and longevity.

The Product Specification

| Item | Value |

|---|---|

| Alloy | 5083 Aluminum Plate |

| Temper | O, H111, H112, H116, H321 |

| Thickness | 0.5–150mm |

| Width | 100-2500mm |

| Application |

Marine structures and shipbuilding (hulls, decks)

Pressure vessels and storage tanks Automotive components Aircraft components Railway cars Cryogenic applications Building and construction materials Signage and billboards Electronic enclosures" |

Why Choose Our 5083 Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.