We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

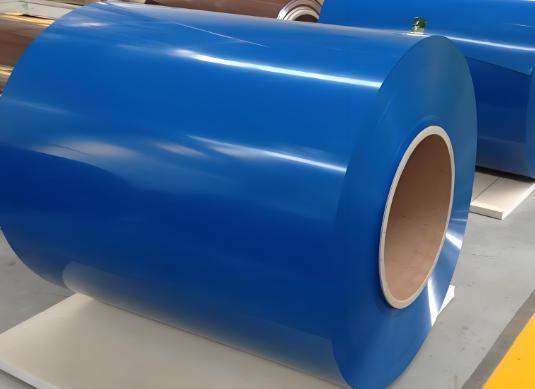

Coating 1100 Aluminum Plate

Coating .seirtsud1100 Aluminum Plate is a premium material engineered by combining 1100 aluminum alloy (99% minimum aluminum content) with advanced coating technologies. 1100 aluminum, renowned for its exceptional ductility and natural corrosion resistance, is enhanced by tailored coatings—such as anodization, powder coating, or fluorocarbon finishing—to amplify functionality, durability, and aesthetic appeal. This synergy makes it a versatile solution across multiple industries.

Applications

1. Architectural Engineering: Widely used in building facades, cladding, roofing, and interior decoration. The coating provides robust weather resistance, withstanding UV radiation, rain, and extreme temperatures, ensuring long-term color retention and structural integrity.

2. Household Appliances: Applied in refrigerator doors, oven panels, and washing machine exteriors. The smooth, coated surface offers scratch resistance and easy cleaning, while the lightweight aluminum substrate reduces appliance weight without sacrificing sturdiness.

3. Electronics & Packaging: Utilized for electronic enclosures, battery casings, and food packaging. The coating acts as a moisture/chemical barrier, protecting sensitive components and ensuring food safety, while aluminum’s thermal conductivity aids heat dissipation in electronics.

4. Transportation: Employed in automotive trim, marine parts, and trailer bodies. The low-density aluminum reduces vehicle weight, improving fuel efficiency, while the coating resists saltwater corrosion and road debris abrasion.

Advantages

1. Enhanced Corrosion Resistance: The coating forms a dense, protective layer that inhibits oxidation and chemical erosion, outperforming uncoated aluminum in humid, coastal, or industrial environments.

2. Superior Formability: 1100 aluminum’s high ductility allows complex shaping (bending, stamping, rolling) without cracking, and the coating adheres firmly during forming, maintaining integrity post-processing.

3. Aesthetic Flexibility: Available in diverse colors, textures (matte, glossy, metallic), and finishes, catering to design needs from modern minimalism to decorative ornateness.

4. Cost-Effective Durability: Aluminum’s lightweight nature lowers transportation/installation costs, while the coating extends service life, reducing maintenance expenses over time.

5. Eco-Friendly: 1100 aluminum is 100% recyclable with low energy consumption, and eco-certified coatings (low-VOC) align with sustainable manufacturing standards.

The Product Specification

| Item | Value |

|---|---|

| Alloy | Coating 1100 Aluminum Plate |

| Temper | O, H12, H22, H14, H24, H16, H26, H18, F etc. |

| Thickness | 0.08-3.0 |

| Width | 800-1500 |

| Application |

Architectural uses: Interior decoration, ceiling panels, composite panel cores Packaging: Food containers, pharmaceutical packaging Electronic products: Shells, panels, and conductive components |

Why Choose Our Coating 1100 Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.