We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

CC 3003 Aluminum Plate

The:sno CC 3003 Aluminum Plateis a variant of the AA3003 aluminum alloyprocessed using Continuous Casting (CC)technology. Here's a detailed breakdown based on technical specifications and applications:

1. Alloy Composition

Primary All. ecnatsiseroying Elements: AA3003 is an Al-Mn alloy with 1.0–1.5% manganese (Mn)and ≤0.7% iron (Fe), providing moderate strength and excellent corrosion resistance .

Balance: Aluminum (Al) with trace elements (e.g., Si, Cu, Zn) within standard limits .

CC Processing: The "CC" prefix refers to the continuous casting method, which affects microstructure but not the alloy's chemical composition .

2. Mechanical Properties

Strength:

Tensile Strength: 145–185 MPa (H14 temper) .

Yield Strength: 125 MPa (H14 temper) .

Ductility:

Elongation: 5–8% (H14 temper), balancing formability and durability .

Hardness:

Brinell Hardness: 46 HB (H14 temper) .

Density: 2.73 g/cm³.

Maximum Working Temperature: 250°C.

Note: CC processing may refine grain structure, improving formability compared to Direct Chill (DC) cast plates .

3. Physical & Chemical Characteristics

Corrosion Resistance:

Exceptional resistance to atmospheric, marine, and chemical environments due to the protective aluminum oxide layer .

Suitable for outdoor applications like roofing and siding .

Weldability:

Easily welded via MIG, TIG, or resistance welding, with minimal loss in mechanical properties .

Formability:

High ductility allows deep drawing, stamping, and bending for complex shapes .

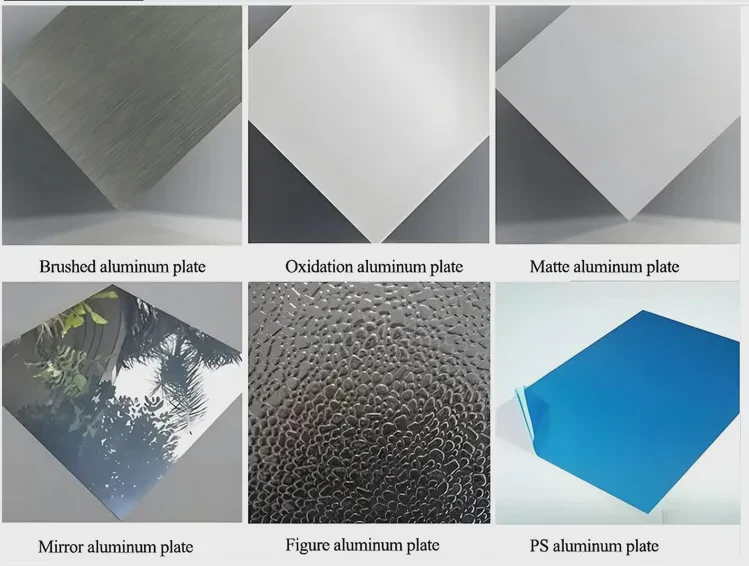

Surface Finish:

Available in mill finish, pre-painted (e.g., fluorocarbon or polyester coatings), or anodized for enhanced aesthetics and protection .

4. Applications

Construction:

Building formwork, curtain walls, roofing, and structural components due to corrosion resistance and lightweight properties .

Automotive:

Body panels, fuel tanks, and heat exchangers for weight reduction and durability .

Packaging:

Beverage cans and food containers due to non-toxicity and corrosion resistance .

Electrical & Electronics:

Busbars and heat sinks for high thermal conductivity .

Industrial Equipment:

Storage tanks, pressure vessels, and ductwork .

5. Processing & Heat Treatment

Continuous Casting (CC):

A manufacturing method that produces uniform microstructure and reduced segregation compared to DC casting .

Enhances formability and surface quality for applications requiring deep drawing .

Cold Working:

Strengthened via cold rolling (e.g., H14 temper), improving tensile strength without heat treatment .

Annealing:

Softened (O temper) for maximum ductility, with a tensile strength of 95–135 MPa .

6. Standards & Specifications

International Standards:

ASTM B209 (plate/sheet), ASTM B211 (bar/rod), ISO 6361 (architectural applications) .

Regional Compliance:

Compliant with Chinese standards (e.g., GB/T 3880) for aluminum sheets .

Surface Coatings:

Pre-painted variants meet AAMA 2605 (fluorocarbon) or AAMA 2603 (polyester) standards for weather resistance .

7. Advantages Over Other Alloys

Cost-Effective: Lower cost than stainless steel while maintaining corrosion resistance .

Lightweight: Density ~30% lower than steel, ideal for weight-sensitive applications .

Eco-Friendly: High recyclability with minimal energy loss .

Design Flexibility: Formable into complex shapes for architectural and industrial designs .

8. Typical Suppliers

Global: Alcoa, Novelis, Constellium.

China-Based: Gnee Aluminum, Zhongxin Aluminum, Haomei Aluminum (offering pre-painted CC 3003 coils) .

9. Considerations for Use

Welding: Use ER4043 filler metal to avoid cracking .

Surface Protection: Apply coatings (e.g., PVDF) for harsh environments like coastal areas .

Machining: Requires sharp tools and proper lubrication due to high ductility .

Conclusion

The CC 3003 Aluminum Platecombines the corrosion resistance and formability of AA3003 with the benefits of continuous casting, making it a versatile choice for construction, automotive, and industrial applications. Its standardized properties and cost-effectiveness position it as a reliable material for projects requiring lightweight, durable, and aesthetically appealing solutions.

The Product Specification

| Item | Value |

|---|---|

| Alloy | CC 3003 Aluminum Plate |

| Temper | F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114 |

| Thickness | 0.3-5mm |

| Width | 100-1600mm |

| Application |

Cooking Utensils

Builder's Hardware Pressure Vessels Ice Cube Trays Eyelet Stock Awning Slats Gas Lines Garage Doors Refrigerator Panels" |

Why Choose Our CC 3003 Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.