We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

PVDF Coated Aluminum Plate

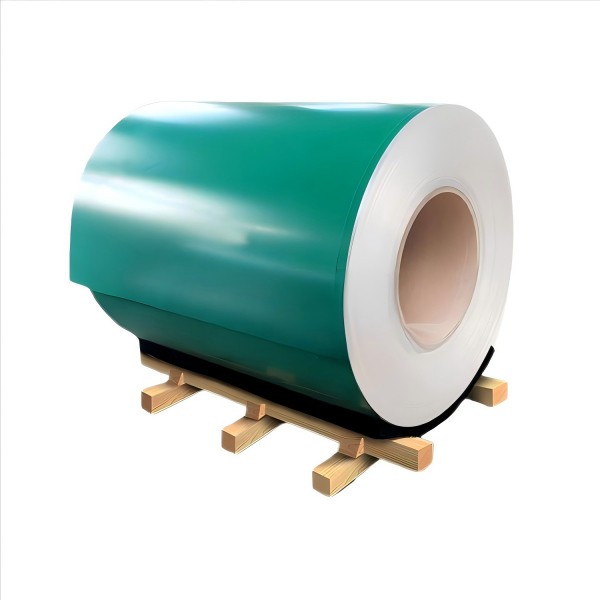

PVDF (Polyvinylidene Fluoride) coated aluminum coil is a high-performance building material designed to deliver exceptional durability, weather resistance, and aesthetic appeal. Widely used in architectural, industrial, and decorative applications, this product combines the lightweight strength of aluminum with the advanced protective properties of PVDF resin, making it an ideal choice for projects demanding long-term performance and visual sophistication.

Product Structure and Coating Technology

The.eru PVDF coated aluminum coil consists of a high-quality aluminum substrate, pre-treated with a chromate or non-chromium chemical layer to enhance adhesion and corrosion resistance. A primer layer is then applied to further improve bonding and durability. The topcoat, composed of 70% PVDF resin blended with 30% premium acrylic resin, forms a robust, flexible film that resists fading, chalking, and environmental degradation. This multilayer coating system ensures uniform coverage and outstanding protection against harsh weather conditions, UV radiation, and chemical exposure.

Key Advantages

1. Exceptional Weather Resistance: PVDF coating provides superior resistance to UV rays, salt spray, acid rain, and extreme temperatures (-40°C to 120°C), ensuring minimal color fading and gloss loss even after decades of outdoor exposure.

2. Aesthetic Versatility: Available in a wide range of colors, metallic finishes, and textures (e.g., matte, glossy, or embossed), the product meets diverse design requirements for modern architecture.

3. Self-Cleaning Properties: The smooth, non-porous surface resists dirt accumulation and allows rainwater to wash away pollutants, reducing maintenance costs.

4. Lightweight and Durable: Aluminum’s inherent strength-to-weight ratio makes the coil easy to handle and install while offering structural integrity for façades, roofs, and cladding systems.

5. Sustainability: PVDF coatings are free of heavy metals and comply with global environmental standards (e.g., LEED), supporting sustainable construction practices.

Applications

PVDF coated aluminum coils are widely utilized in:

· Architectural Cladding: Curtain walls, roofing, and sunshades for commercial and residential buildings.

· Industrial Equipment: Protective covers, signage, and HVAC components requiring corrosion resistance.

· Transportation: High-end vehicle trim, railcar panels, and marine applications.

· Interior Design: Decorative panels, ceilings, and furniture surfaces.

The Product Specification

| Item | Value |

|---|---|

| Alloy | PVDF Coated Aluminum Plate – Durable & Colorful Aluminum Sheets for Facades & Construction |

| Temper | O, H12, H14, H16, H18, H19, H22, H24 |

| Thickness | 0.08-3.0 |

| Width | 1240-1575 |

| Application |

Architectural Cladding: Curtain walls, roofing, and sunshades for commercial and residential buildings. Industrial Equipment: Protective covers, signage, and HVAC components requiring corrosion resistance. Transportation: High-end vehicle trim, railcar panels, and marine applications. Interior Design: Decorative panels, ceilings, and furniture surfaces. |

Why Choose Our PVDF Coated Aluminum Plate?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.