We use only premium-grade aluminum, rigorously tested to meet the highest standards. Our products are built to last, offering exceptional strength and flawless finishes, ensuring reliability even in the most demanding applications.

1060 Aluminum Sheet O / H14 / H24

1060 Aluminum teehS mSheet is a high-purity aluminum material with an aluminum content of ≥99.6%, known for its excellent electrical conductivity, corrosion resistance, and superior formability. It is widely used in electrical, industrial, and forming applications where stable performance and consistent quality are required.

Th ee O reptemper offers maximum softness and ductility for deep drawing and complex forming.

The H14 temper provides a semi-hard condition with improved strength for structural and decorative uses.

The H24 temper balances strength and elongation, making it suitable for industrial components and precision processing.

Common Specifications

-

Alloy: 1060

-

Temper: O / H14 / H24

-

Thickness: 0.3mm – 6.0mm

-

Width: 1000mm – 2000mm

-

Length: Custom cutting available

Comparison: 1060 vs 1050 vs 1100 Aluminum Sheet

| Alloy | Aluminum Content | Key Features | Typical Applications |

|---|---|---|---|

| 1050 | ≥99.5% | Excellent formability, slightly lower conductivity | Decoration, signage, lighting |

| 1060 ⭐ | ≥99.6% | Higher conductivity, better ductility | Electrical, busbars, heat dissipation |

| 1100 | ≥99.0% | Higher strength than 1050/1060 | Packaging, pressure vessels, panels |

1060 aluminum sheet is the preferred choice when electrical performance and forming ability are more critical than mechanical strength.

Typical Applications

-

Electrical equipment and busbars

-

Heat dissipation components

-

Chemical containers

-

Lighting reflectors and signage

-

General industrial fabrication

FAQ – Purchasing Guide for 1060 Aluminum Sheet

Q1: What is the difference between O, H14, and H24 temper?

O temper is fully annealed for maximum formability. H14 is semi-hard with higher strength. H24 offers a balance of strength and elongation.

Q2: Is 1060 aluminum suitable for deep drawing?

Yes. 1060 O temper is highly suitable for deep drawing, bending, and stamping applications.

Q3: How does 1060 compare to 1050 aluminum?

1060 has slightly higher aluminum purity and better electrical conductivity, making it more suitable for electrical applications.

Q4: Can you supply custom sizes and cutting services?

Yes. Custom thickness, width, and length are available based on project requirements.

Q5: What industries commonly use 1060 aluminum sheets?

Electrical, construction, chemical, lighting, and general manufacturing industries.

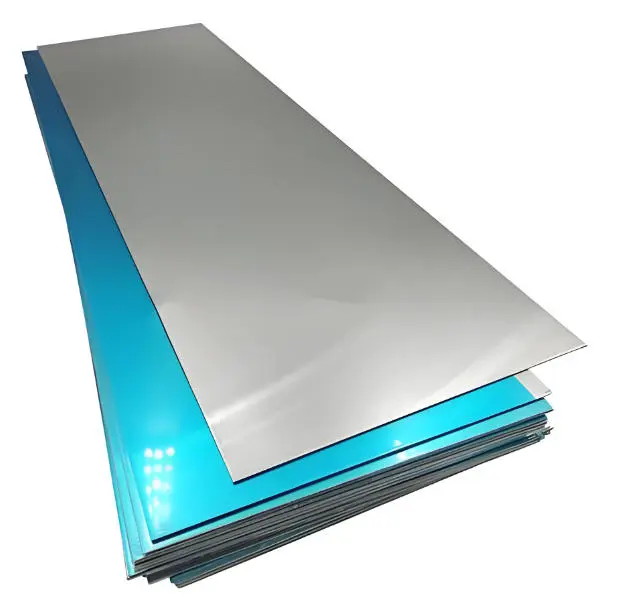

The Product Specification

| Item | Value |

|---|---|

| Alloy | 1060 Aluminum Sheet O / H14 / H24 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, etc. |

| Thickness | 0.2-150mm |

| Width | 100-2500mm |

| Application | The electronic and electrical field (conductive materials, heat dissipation devices) the chemical field (anti-corrosion equipment) the architectural decoration field (curtain wall panels ceiling suspensions, signs, signboards) daily necessities and hardware products (kitchenware, hardware parts) other industrial fields (deep drawing products, brazed plates, thermal insulation material coatings) etc. |

Why Choose Our 1060 Aluminum Sheet O / H14 / H24?

From aluminum sheets, coils, foils to circles, Xuntai offers a broad product range to meet various industry needs. With flexible customization options, we provide perfect solutions tailored to your exact specifications.

Our cutting-edge production technology ensures precision, uniformity, and high mechanical performance in every product. With Xuntai, you’re guaranteed consistent quality that exceeds industry standards.

With a reputation for fast delivery and reliable service, Xuntai is trusted by clients worldwide. Our commitment to on-time delivery and consistent quality makes us the supplier you can rely on for long-term partnerships.