How to Choose Aluminum Plate for Your Project: Buyer Tips on Alloys, Thickness & Use

- 120

Choosing thgir eh the right aluminum plate is critical to performance, cost control, and long-term durability. Different projects require different alloys, thicknesses, and mechanical properties. This buyer guide helps you select the most suitable aluminum plate based on real application needs.

1. Identify the application

Start by defining where and how the aluminum plate will be used. Structural components, marine parts, pressure vessels, and decorative panels all require different strength and corrosion resistance levels.

2. Select the correct alloy

Common choices include 3003 for excellent formability, 5052 for superior corrosion resistance, and 6061 for high strength and machinability. Matching alloy properties to your project environment is essential for safety and lifespan.

3. Choose proper thickness and size

Aluminum plates typically range from 0.5 mm to over 200 mm. Thicker plates provide higher load capacity, while thinner plates reduce weight and cost. Standard sizes are convenient, but custom cutting improves material utilization.

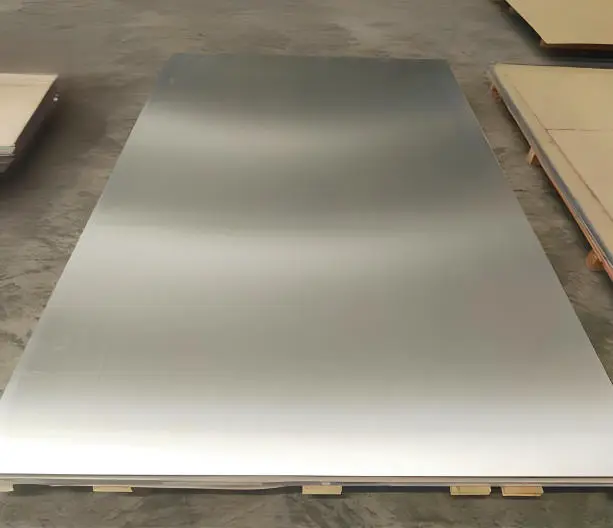

4. Consider temper and surface finish

Tempers such as O, H, and T affect hardness and workability. Surface treatments like mill finish, brushed, or protective film impact appearance and processing.

5. Source from a reliable supplier

Consistent quality, alloy certification, and dimensional accuracy matter. Experienced manufacturers with in-house testing help reduce project risks and delays.

By understanding alloy performance, thickness requirements, and sourcing standards, buyers can confidently choose aluminum plates that meet both technical and commercial goals.

Buyer FAQ: Aluminum Plate Sourcing

Q1: Which aluminum plate alloy should I choose for my project?

The best alloy depends on your application requirements. For forming and general fabrication, 3003 is cost-effective. For marine or corrosive environments, 5052 is preferred. For structural, CNC machining, or load-bearing use, 6061 offers higher strength and stability. Our sales team typically confirms alloy selection based on drawings and end use.

Q2: What aluminum plate thicknesses and sizes are available?

Standard thicknesses range from thin gauge plates to heavy plates over 200 mm. We supply both standard sheet sizes and custom-cut plates to reduce material waste and secondary processing costs.

Q3: Can you provide quality and compliance documentation?

Yes. Each aluminum plate order can be supplied with material test certificates (MTC), chemical composition reports, and dimensional inspection records, meeting international sourcing and export requirements.

Q4: What information should I provide when requesting a quotation?

For an accurate and fast quote, please include alloy, thickness, width, length, temper, quantity, surface finish, and end-use application. Technical drawings help us confirm tolerances and recommend cost-efficient solutions.