What Is an Aluminum Circle? Properties, Grades and Applications

- 176

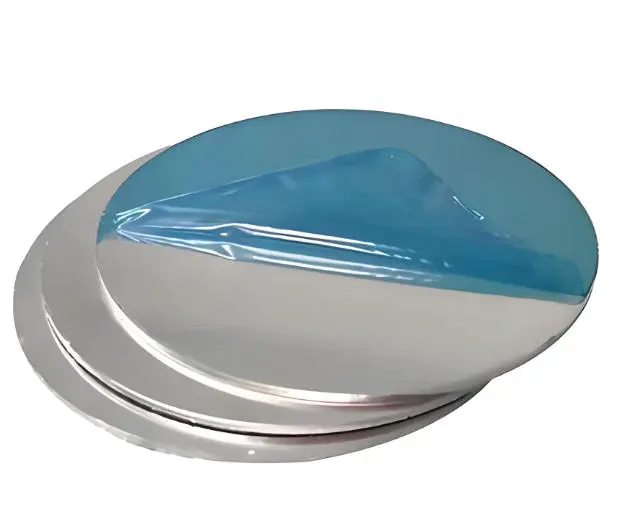

An aluminum cirelcriccle, also known as an aluminum disc or aluminum blank, is a round-shaped aluminum product punched or cut from aluminum sheets or coils. It is widely used in cookware, lighting, electrical, and general industrial applications where uniform thickness, good formability, and stable surface quality are required.

Key PrelcriC operties of Aluminum Circle

Aluminum circles are valued for their lightweight structure, corrosion resistance, and excellent thermal conductivity. They offer good deep-drawing and spinning performance, making them suitable for products that require smooth forming without cracking. In addition, aluminum circles are easy to recycle, aligning with sustainability requirements in many global markets.

Common Aluminum Circle Grades

The most commonly used aluminum circles belong to the 1xxx series, known for high aluminum purity and stable performance:

-

1050 Aluminum Circle: High purity, good corrosion resistance, suitable for simple forming applications.

-

1060 Aluminum Circle: Better mechanical strength than 1050, widely used in cookware and lighting components.

-

1100 Aluminum Circle: Excellent formability and surface finish, often used for decorative and precision applications.

These grades comply with international standards such as ASTM, EN, and GB, depending on market requirements.

Typical Applications

Aluminum circles are commonly used in cookware (pots, pans, pressure cookers), lighting reflectors, traffic signs, electrical housings, and industrial covers. Their consistent thickness and controlled tolerances ensure reliable performance during further processing.

Manufacturing and Quality Control

High-quality aluminum circles are produced through controlled rolling, annealing, and precision blanking processes. Stable raw materials, strict dimensional inspection, and surface quality checks are essential to ensure each circle meets forming and application requirements.