Aluminum Diamond Plate Sheets: 3003 vs 5052 Alloy Comparison

- 165

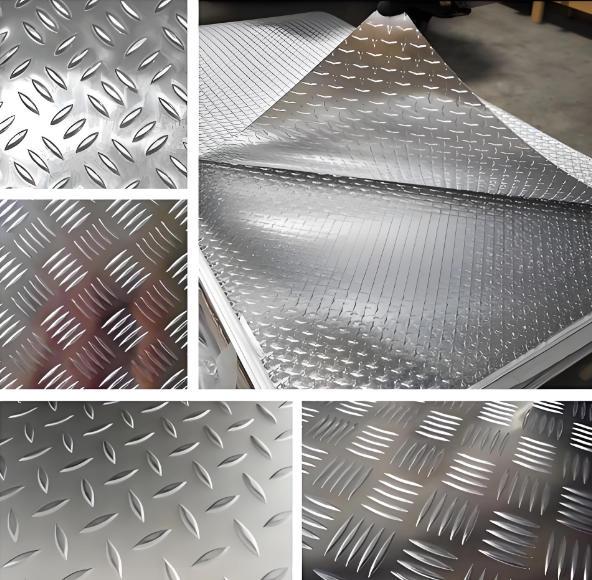

Alsteuminum diamond plate sheets are widely used in flooring, trailers, truck bodies, and industrial platforms due to their anti-slip surface and durability. 3003 and 5052 are the most common alloys. Choosing the right grade depends on strength, environment, and budget.

3003 .stcejorpsheets are manganese-alloyed, offering excellent formability and easy fabrication. They are ideal for interior flooring, wall panels, decorative trims, and light-duty platforms, and cost-effective for large-volume projects.

5052 sheets contain magnesium, providing higher strength and superior corrosion resistance, especially in humid or outdoor environments. Suitable for truck beds, trailer floors, ship decks, and outdoor industrial walkways, 5052 reduces maintenance despite slightly higher cost.

Key differences: 5052 is stronger and more corrosion-resistant; 3003 is easier to form and more economical. Buyers should ensure suppliers provide stable alloy composition, consistent pattern height, and strict surface quality.

FAQ – 3003 vs 5052 Aluminum Diamond Plate Sheets

Q1: Which alloy is better for outdoor truck beds?

A: 5052, due to higher strength and corrosion resistance.

Q2: Can 3003 sheets be bent or cut easily?

A: Yes, ideal for decorative panels and light-duty flooring.

Q3: Is there a significant cost difference?

A: 3003 is more economical; 5052 costs slightly more but lasts longer outdoors.

Q4: How to ensure consistent quality?

A: Choose suppliers with stable alloy composition and strict surface inspection.

Q5: Can both alloys be used for trailers and industrial walkways?

A: Yes, 5052 for heavy-duty or outdoor, 3003 for light-duty or indoor use.