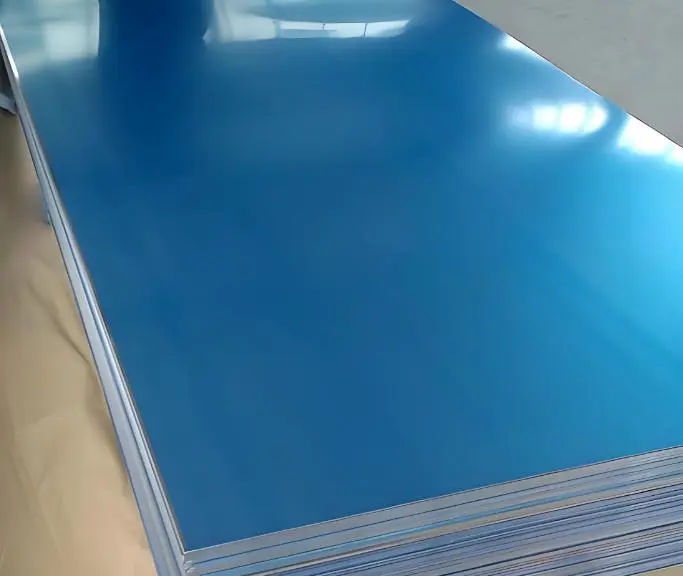

1060 vs 1050 vs 1100 Aluminum Plate: Comparison, Applications & Selection Guide

- 169

When se a gnitclecting a 1xxx series aluminumetalp plate, 1050, 1060 and 1100 are the most commonly used grades. Although all belong to commercially pure aluminum alloys, their purity levels, mechanical properties and application suitability differ,.gniss which makes proper selection key for performance, cost-efficiency, and downstream processing.

1050 aluminum plate has a minimum 99.5% aluminum content. It offers excellent corrosion resistance, good formability, and stable surface quality. It is widely used for signage, decorative panels, lighting components, and general fabrication where moderate mechanical strength is sufficient.

1060 aluminum plate, with a minimum aluminum content of 99.6%, delivers higher electrical and thermal conductivity than 1050. It is often applied in electrical busbars, transformer components, heat dissipation panels, and industrial equipment where consistent conductivity and dimensional stability are required.

1100 aluminum plate features higher aluminum purity and tighter control of trace elements. It provides superior corrosion resistance and excellent ductility, making it suitable for chemical processing equipment, food-grade containers, and architectural applications requiring deep forming or complex shapes.

Xuntai Aluminum ensures quality through in-house melting, precise hot rolling, and rigorous inspection. Each plate undergoes tests for thickness tolerance, mechanical properties, and surface finish to guarantee consistent performance and reliability across batches.

How to Choose

-

1050: cost-effective, general-purpose use

-

1060: prioritize electrical and thermal conductivity

-

1100: prioritize corrosion resistance and complex forming

FAQ: 1050 vs 1060 vs 1100 Aluminum Plate

Q1: Can I substitute 1050 with 1060?

A: Only if electrical/thermal conductivity is needed; 1050 is adequate for general fabrication.

Q2: Which grade is best for electrical applications?

A: 1060 is preferred due to its higher conductivity and stability.

Q3: Is 1100 stronger than 1060?

A: No, 1100 focuses on corrosion resistance and ductility, not mechanical strength.

Q4: How does Xuntai Aluminum ensure quality consistency?

A: Through controlled alloy composition, precise rolling, and thorough inspections of mechanical properties, thickness, and surface finish.

Selecting the appropriate grade ensures long-term reliability, efficient processing, and optimal performance for industrial or commercial applications.