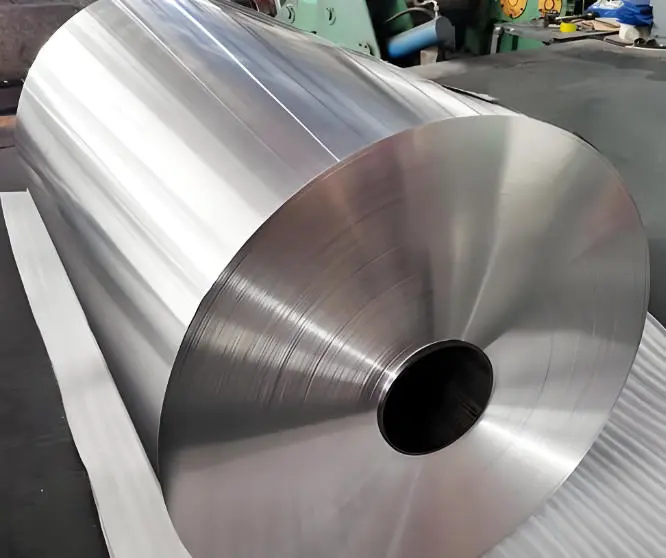

3003 H14 Aluminum Coil for Sale: Thickness, Width & Standards Guide

- 36

3003 H14 aluminum coil is one o.gnisf the most widely used aluminum alloys in construction, insulation, and industrial fabrication due to its excellent corrosion resistance, good formability, and stable mechanical strength. As a non-heat-treatable alloy strengthened by cold working, 3003 H14 offers a balanced combination of durability and workability for large-scale processing.

This alloy contains manganese as its primary alloying element, which significantly improves strength compared to pure aluminum while maintaining excellent bending and forming performance. The H14 temper indicates a half-hard condition, making it suitable for roll forming, stamping, and light drawing applications without cracking.

3003 H14 aluminum coil thickness typically ranges from 0.2 mm to 6.0 mm, while common width options include 300–1600 mm, with custom slitting available upon request. Standard inner diameters are 508 mm and 610 mm, allowing compatibility with most processing equipment.

In terms of standards, 3003 H14 aluminum coil is commonly produced according to ASTM B209, EN 485, and JIS H4000, ensuring consistent chemical composition, mechanical properties, and dimensional tolerance for international projects.

Thanks to its corrosion resistance and surface quality, 3003 H14 aluminum coil is widely used in roofing sheets, wall cladding, insulation jacketing, HVAC systems, storage tanks, and transportation components. It is also suitable for surface treatments such as coating, embossing, and anodizing.

When choosing 3003 H14 aluminum coil for sale, buyers should consider thickness tolerance, width accuracy, surface finish, and compliance with required standards. Reliable suppliers can also provide customized sizes, stable MOQ options, and quality inspection reports to meet different project needs.