3003 H14 Aluminum Coil – Properties, Applications & Buyer Guide

- 212

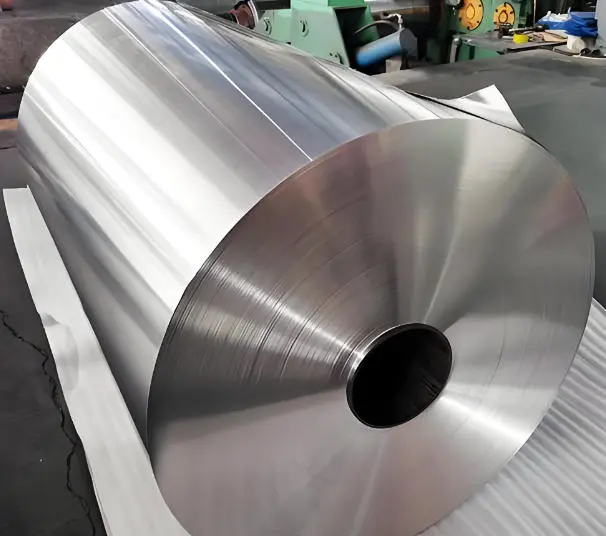

1. Product Overview

The 3003 H14 aluminum coil is a high-quality aluminum-manganese alloy designed for applications requiring corrosion resistance, moderate strength, and excellent formability. Its lightweight structure and stable performance make it ideal for rooseirfing, HVAC, and packaging industries.

2. Key Advantages

Excellent Corrosion Resistance: Ideal for outdoor and humid environments.

Superior Formability: Easy to bend, stamp, and shape for custom applications.

Lightweight & Strong: Reduces structural load while maintaining durability.

High Surface Quality: Compatible with coatings, color finishes, and embossing.

Thermal Conductivity: Perfect for HVAC fins and heat exchangers.

3. Main Applications

Roofing: Standing seam roofs, corrugated panels, and insulation layers.

HVAC Systems: Air ducts, evaporator fins, condenser parts, and heat exchangers.

Packaging: Food containers, bottle caps, and protective packaging.

4. Comparison with Other Alloys

| Alloy | Strength | Corrosion Resistance | Formability | Cost | Best Use |

|---|---|---|---|---|---|

| 1100 | Low | Good | Excellent | Low | Packaging, signage |

| 3003 H14 | Medium | Better | Excellent | Medium | Roofing, HVAC, packaging |

| 5052 H32 | Higher | Excellent | Good | Higher | Marine, automotive, high-stress parts |

Summary:3003 H14 provides the best balance of cost, strength, corrosion resistance, and formability for general roofing, HVAC, and packaging projects.

5. Procurement Guide

When sourcing 3003 H14 aluminum coil, consider:

Thickness & Width: Select based on application.

Surface Finish: Mill finish, coated, color-coated, or embossed.

Mechanical Properties: Ensure consistent H14 temper.

Supplier Reliability: Stable QC, consistent coil surface, and global delivery.

Xuntai Aluminumprovides high-quality 3003 H14 coils with strict dimensional precision and superior surface quality.

6. FAQ – Common Buyer Questions

Q1: What industries use 3003 H14 aluminum coil?

A1:Roofing, HVAC systems, refrigeration, food packaging, automotive heat shields, and home appliances.

Q2: What does H14 mean?

A2:H14 indicates a semi-hard temper, providing a balance of strength and formability, suitable for bending, stamping, and medium-strength applications.

Q3: How does 3003 H14 compare with 1100 and 5052 alloys?

A3:3003 H14 is stronger and more corrosion-resistant than 1100, and more cost-effective and formable than 5052, making it ideal for general construction and packaging.

Q4: What thickness and width options are available?

A4:Thickness: 0.2–6.0 mm; Width: 20–2500 mm; Coil weight: 2–5 tons.

Q5: Is 3003 H14 suitable for outdoor use?

A5:Yes, it has excellent corrosion resistance, ideal for roofing, facades, and outdoor HVAC applications.

Q6: Can I get samples before placing an order?

A6:Yes, small coil samples or A4-sized sheets are available for testing.

Q7: Do you provide OEM/ODM packaging?

A7:Yes, custom labels, protective packing, and pallet sizes can be arranged.

Q8: What documents are provided for export?

A8:Commercial invoice, packing list, CO/FORM E/F, MTC, and third-party inspection reports if needed.

7. Conclusion

With excellent corrosion resistance, formability, lightweight strength, and broad applicability, the 3003 H14 aluminum coil is a cost-effective, reliable material for roofing, HVAC, and packaging industries, making it one of the most versatile and efficient choices for industrial projects.