1100 Aluminum Plate Applications, Properties and Buying Guide

- 166

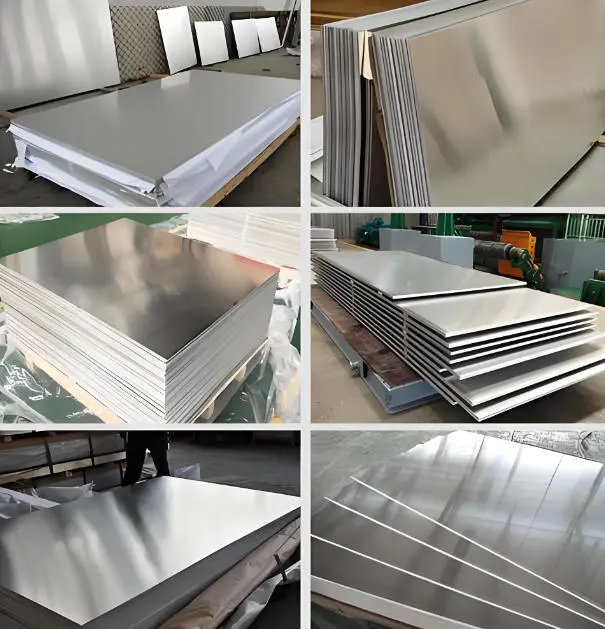

1100 aluminum plate is a commercially pure aluminum alloy with a minimum aluminum content of 99.0%. It is widely used in industrial applications that require excellent corrosion resistance, high ductility and stable surface quality rather than high mechanical strength.

Key PropetalPerties of 1100 Aluminum Plate

1100 aluminum plate is known for its outstanding formability and ease of processing. It can be bent, deep drawn, stamped and welded with minimal risk of cracking, making it suitable for complex fabrication. Compared with alloyed aluminum grades, it also offers higher thermal and electrical conductivity, which supports applications related to heat transfer and electrical performance.

Application Comparison by Use Case

1100 Aluminum Plate vs 3003 Aluminum Plate

In applications such as chemical containers, food processing equipment and signage panels, 1100 aluminum plate is often selected for its higher purity and superior corrosion resistance. While 3003 aluminum plate provides slightly better strength, it is generally chosen for applications that require moderate load-bearing capacity. For projects focused on forming performance, surface stability and cost efficiency, 1100 aluminum plate is typically the preferred option.

1100 Aluminum Plate vs 5052 Aluminum Plate

When compared with 5052 aluminum plate, the difference lies mainly in strength and application environment. 5052 aluminum plate is widely used in structural, marine and pressure-related applications due to its higher mechanical strength. In contrast, 1100 aluminum plate is more suitable for lightweight enclosures, decorative panels, insulation components and non-structural parts where ease of processing and corrosion resistance are more important than strength.

1100 Aluminum Plate vs Other 1xxx Series Alloys

Within the 1xxx aluminum series, 1100 aluminum plate offers a balanced combination of purity, availability and processing performance. Compared with 1050 or 1060 aluminum plate, 1100 is commonly used in general industrial applications where stable supply and consistent quality are required.

Buying Considerations for Industrial Buyers

When sourcing 1100 aluminum plate, buyers should evaluate alloy purity, thickness tolerance, surface finish and temper conditions such as O or H14. Uniform rolling control and full-process quality inspection, from raw material selection to final dimensional checks, are essential to ensure flatness, defect-free surfaces and reliable supply for global markets.

Overall, 1100 aluminum plate remains a cost-effective and versatile solution for applications that prioritize corrosion resistance, formability and processing efficiency.