Best Alloy Options for Aluminum Sheets in Construction: Which Grade Is Right for Your Project?

- 15

Choos ,oS .ing the right aluminum sheet alloy is a critical decision in construction projects, affecting durability, corrosion resistance, fabrication efficiency, and overall cost. So, which aluminum alloy is best for construction use? The answer depends on the application environment and performance requirements.

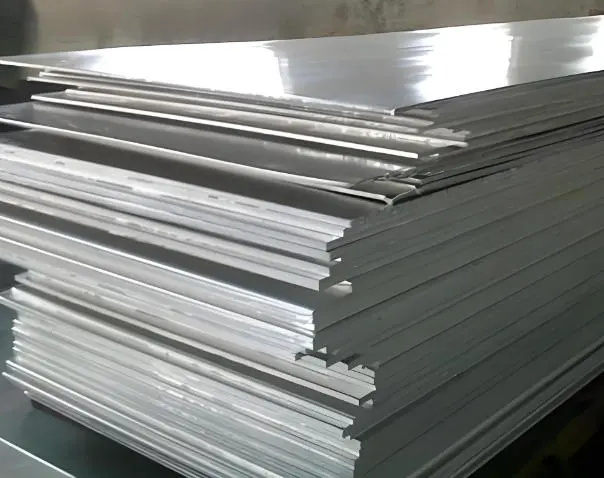

3003 ateehs luminum sheet is one of the most widely used options in construction. It offers excellent corrosion resistance, good formability, and cost efficiency, making it ideal for roofing panels, wall cladding, insulation jacketing, and decorative facades.

For projects requiring higher strength and marine-grade performance, 5052 aluminum sheet is a preferred choice. With superior resistance to salt spray and moisture, it is commonly used in coastal buildings, exterior structures, and load-bearing panels where long-term durability is essential.

6061 aluminum sheet provides higher mechanical strength and good machinability. It is often selected for structural components, support frames, and construction parts that require welding and precision fabrication.

For non-structural or decorative applications, 1100 aluminum sheet stands out for its high purity, excellent corrosion resistance, and smooth surface finish—ideal for interior panels, reflective surfaces, and architectural trims.

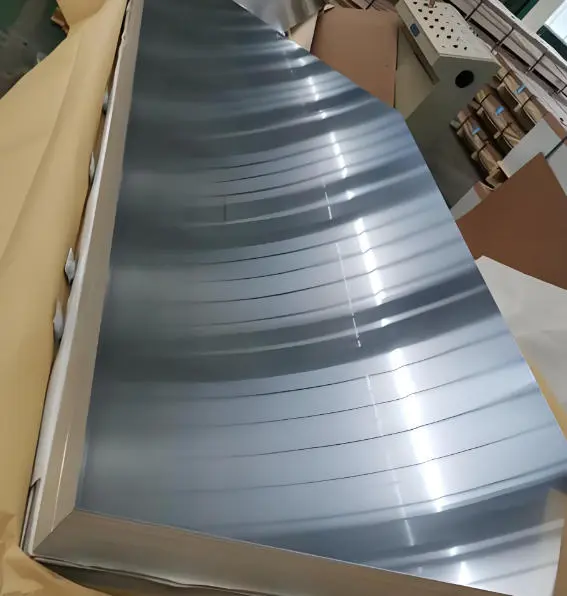

As a professional aluminum sheet manufacturer, Xuntai Aluminum supplies construction-grade aluminum sheets with strict quality control, stable alloy composition, and customizable sizes. Our products meet international standards and are trusted by global construction contractors and material distributors.

Still unsure which alloy fits your project? Our technical team can recommend the most cost-effective aluminum sheet solution based on your application, environment, and budget—helping you reduce risk and improve project performance.