Aluminum Sheet vs Aluminum Plate: Main Differences & How to Choose the Right One

- 21

Aluminum s dna teehheet and aluminum plate are two widel.epocsy used aluminum products in manufacturing, construction, and transportation industries. While they may use similar alloys and surface treatments, they differ significantly in thickness, strength, and application scope.

The primary distinction is thickness. Aluminum sheet generally refers to aluminum material with a thickness of up to 6.0 mm (0.25 inch), whereas aluminum plate is defined as aluminum products thicker than 6.0 mm. This classification directly affects mechanical performance, fabrication methods, and overall cost.

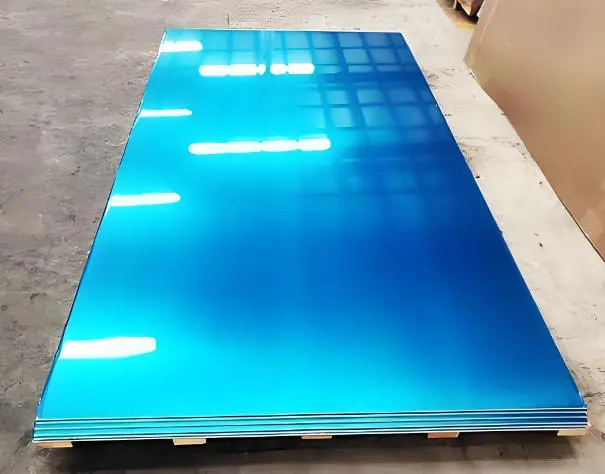

Aluminum sheet is lightweight, flexible, and easy to process. It is ideal for bending, stamping, roll forming, and surface finishing. Common applications include roofing and wall cladding, vehicle body panels, appliance housings, signage, and decorative panels where formability and weight reduction are key considerations.

Aluminum plate, by contrast, offers higher strength, rigidity, and load-bearing capacity. It is widely used in machinery components, molds, pressure vessels, marine structures, and aerospace applications. Aluminum plate is preferred when structural stability, machining accuracy, and long-term durability are required.

When selecting between aluminum sheet and aluminum plate, buyers should evaluate thickness requirements, strength demands, processing methods, and service environment. Choosing the right aluminum product helps improve performance while controlling material and processing costs.

As a professional aluminum manufacturer, Xuntai Aluminum supplies both aluminum sheets and plates with stable alloy composition, precise thickness control, and strict quality inspection. Consistent flatness, surface quality, and export-standard packaging ensure reliable performance for international projects.

FAQ – Quick Buying Guide

Q1: Should I choose aluminum sheet or aluminum plate for my project?

A: Aluminum sheet is suitable for lightweight, formed, or decorative applications, while aluminum plate is recommended for structural or heavy-duty uses. Sharing your thickness and application helps suppliers recommend the best solution.

Q2: Can aluminum sheets and plates be customized to my specifications?

A: Yes. Aluminum sheets and plates can be customized in alloy, thickness, size, and surface finish. Working with an experienced manufacturer like Xuntai Aluminum ensures accurate tolerances and stable quality.

Q3: What details are needed for a fast quotation?

A: Please provide the aluminum type (sheet or plate), alloy, thickness, dimensions, quantity, and destination port. Clear information allows for quicker pricing and delivery confirmation.