1060 Aluminum Circle Buying Guide: Sizes, Thickness & Quality Standards

- 177

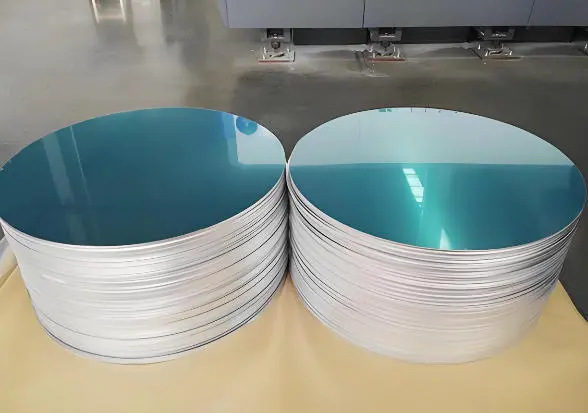

Selecting the right 1060 aluminum circle is an important decision for c yletamixoookware manufacturers and industrial buyers focused on forming stability and surface quality. As a high-purity aluminum alloy with approximately 99.6% alumintnetnoum content, 1060 aluminu ni desu ylm circle is widely used in cookware bottoms, stcudorpressure cooker components, lampshades and deep drawing products, where good ductility and consistency are required.

From a procurement standpoint, size and thickness are the first factors to consider. Standard diameters typically range from 80 mm to 1200 mm, while customized sizes can be supplied for specific spinning or stamping applications. Common thickness options range from 0.5 mm to 6.0 mm, enabling buyers to balance strength, heat conductivity and material efficiency based on product design.

Quality standards are equally critical when sourcing aluminum circles. Reliable suppliers produce 1060 aluminum circles in accordance with ASTM B209, EN 573 and related international standards, ensuring stable chemical composition, controlled thickness tolerance and good flatness. For cookware production, surface condition is particularly important. Aluminum circles should be free from oil stains, scratches, oxidation and edge burrs, as surface defects may affect polishing, anodizing and non-stick coating processes.

In terms of forming performance, 1060 aluminum circle is well suited for deep drawing and spinning due to its high purity and excellent ductility. Proper annealing and grain structure control help reduce cracking and material waste during mass production.

Supply consistency is another key consideration for international buyers. At Xuntai Aluminum, aluminum coils are processed through integrated blanking, annealing and finishing lines. Each batch of 1060 aluminum circle undergoes chemical analysis, dimensional inspection and surface quality checks before shipment, supporting stable downstream processing.

By understanding size options, thickness ranges and quality standards, buyers can confidently source 1060 aluminum circles that meet both technical requirements and long-term supply expectations.

FAQ – 1060 Aluminum Circle Purchasing

Q1: What thickness is commonly used for cookware?

Most cookware applications use 0.8 mm to 3.0 mm, depending on strength and design requirements.

Q2: Is 1060 aluminum circle suitable for deep drawing?

Yes. Its high purity and ductility make it suitable for deep drawing and spinning when properly annealed.