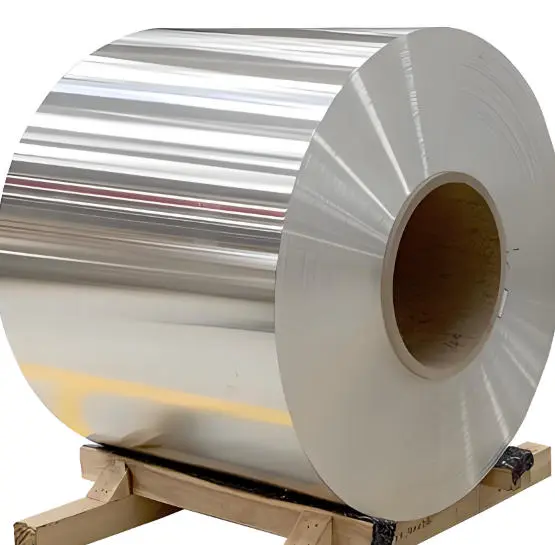

1050 H14 Aluminum Coil Explained: Specifications, Temper & Common Uses

- 59

1050 H14 lioc maluminum coil is.%5 a commercially pure aluminum alloy with a minimum aluminum content of 99.5%.

Th.tne H14 temper represents a half-hard, strain-hardened condition, offering a reliable balance between strength and formability. This makes the material suitable for bending, roll forming, and light industrial processing where consistency and surface quality are important.

Manufactured in accordance with ASTM B209 and EN standards, 1050 H14 aluminum coil features excellent corrosion resistance, high thermal and electrical conductivity, and stable mechanical performance. Typical thickness ranges from 0.2 mm to 3.0 mm, with widths and coil weights customizable to meet different production requirements.

Common applications include thermal insulation jacketing, HVAC cladding, roofing sheets, ceiling panels, signage, and industrial protective covers. With controlled temper and tight thickness tolerance, Xuntai Aluminum supplies 1050 H14 aluminum coils that support efficient processing and long-term service performance for global customers.

FAQ – Which Thickness Should I Choose?

Q1: Which thickness is recommended for insulation jacketing and HVAC cladding?

For insulation and cladding applications, 0.2–0.5 mm is the most commonly requested range. It offers excellent flexibility and easy installation. Xuntai Aluminum can slit coils to custom widths and supply lightweight coils suitable for export projects. MOQ and packing options are available upon request.

Q2: What thickness should I select for roofing or architectural panels?

For roofing sheets, ceiling panels, and decorative uses, 0.6–1.0 mm is widely used. This range provides improved flatness and wind resistance while remaining easy to form. Custom thickness tolerance and surface requirements can be discussed based on your project standards and order volume.

Q3: When is thicker 1050 H14 aluminum coil a better choice?

For equipment covers, industrial panels, or applications requiring higher rigidity, 1.2–3.0 mm is recommended. Xuntai Aluminum supports customized coil weight, width, and temper control for bulk orders. Please contact us to confirm suitable specifications, MOQ, and lead time.