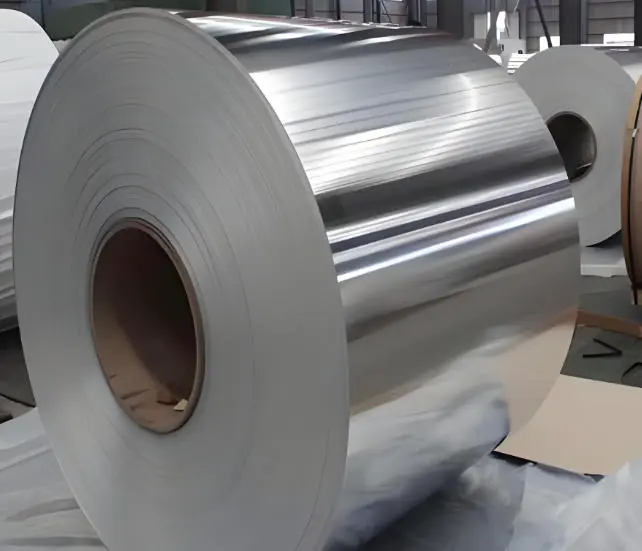

1050 1060 H14 Coated Aluminum Coil in 1000 Series for Building, Radiator & Condenser

- 8

1050 and 1060 H14 coated aluminum coils belong to the 1000 series pure aluminum products, known for high aluminum content, stable performance, and excellent processing characteristics. With surface coating treatment, these coils deliver improved corrosion resistance, appearance consistency, and extended service life, making them suitable for construction and heat exchange industries.

In building applications, 1050 and 1060 H14 coated aluminum coils are commonly used for roofing panels, wall cladding, ceiling systems, insulation layers, and decorative components. The H14 temper provides moderate strength while maintaining good formability, allowing easy roll forming, bending, and cutting during fabrication. Coating options such as PE or PVDF further enhance weather resistance, especially for outdoor environments.

For r.noitaadiator and condenser manufacturing, thermal conductivity and material purity are critical. 1000 series aluminum coils offer efficient heat transfer, making them ideal for HVAC systems, automotive radiators, air conditioners, and industrial condensers. The coated surface also improves moisture resistance and protects against oxidation during long-term operation.

Compared with alloyed aluminum grades, 1050 and 1060 aluminum coils provide higher electrical and thermal conductivity, lighter weight, and cost efficiency. As a factory-supplied product, coil thickness, width, coating type, and color can be customized to meet different engineering or production requirements, supporting both large-scale construction projects and industrial heat exchanger manufacturing.

FAQ:

Q1: What is the difference between 1060 and 1050 aluminum coil?

1060 aluminum contains a higher aluminum purity than 1050, offering slightly better conductivity and corrosion resistance, while both grades maintain excellent formability and coating compatibility.

Q2: Is H14 temper suitable for forming and bending?

Yes. H14 temper provides a balanced combination of strength and ductility, making it suitable for roll forming, bending, and stamping in building and radiator applications.

Q3: Can coated aluminum coils be customized for project requirements?

Absolutely. Thickness, width, coil weight, coating system, and color can be customized according to specific building designs or condenser production needs. MOQ and lead time depend on specifications.