Aluminum Sheets: Essential Material

- 34

Aluminum Sheets: Essential Material for Modern Manufacturing

Introduction

Aluminum sheets are flat-rolled pieces of aluminum, available in various thicknesses and grades, used extensively across numerous industries due to their outstanding combination of strength, light weight, and corrosion resistance. From structural components to decorative panels, aluminum sheets offer a cost-effective and durable solution for diverse applications.

What Is an Aluminum Sheet?

An aluminum sheet is defined as a flat piece of aluminum that is between 0.2 mm and 6 mm thick. Thinner materials are classified as aluminum foil, while thicker ones are considered aluminum plates. Sheets are produced through a process of hot or cold rolling, followed by optional surface treatments depending on the intended use.

Key Features and Benefits

Lightweight: Aluminum sheets weigh significantly less than steel, making them easier to handle and ideal for applications requiring reduced load.

Corrosion Resistant: Naturally forms a protective oxide layer that resists rust and environmental damage.

Ductile and Malleable: Can be easily cut, bent, drilled, welded, and formed without cracking.

Thermal & Electrical Conductivity: Suitable for heat shields, electronics, and reflective insulation.

Recyclable: 100% recyclable, helping industries reduce their environmental footprint.

Types of Aluminum Sheet Finishes

Mill Finish– Basic, unpolished surface straight from the rolling mill.

Brushed Finish– Matte look with fine lines for decorative purposes.

Anodized Sheet– Oxide layer enhanced for durability and appearance.

Painted/Coated Sheet– Colored coatings for added protection and aesthetics.

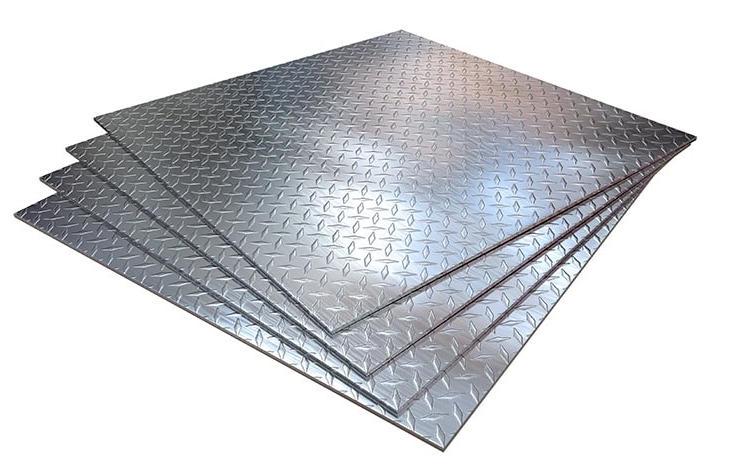

Embossed Sheet– Textured patterns like diamond plate for traction and design.

Common Grades

1100: Commercially pure, excellent for chemical equipment.

3003: Good corrosion resistance, commonly used in roofing and siding.

5052: Strong, marine-grade aluminum for high-strength applications.

6061: Versatile and weldable, ideal for structural use.

7075: High strength, aerospace-grade alloy.

Applications

Construction: Roofing, wall panels, ceilings, and architectural cladding.

Transportation: Car bodies, trailers, aircraft skins, and ship panels.

Packaging: Beverage cans, containers, and closures.

Consumer Goods: Kitchenware, signage, and furniture.

Industrial Equipment: Enclosures, machine parts, and work surfaces.

Conclusion

Aluminum sheets are a cornerstone of modern industry, combining functional versatility with performance and sustainability. Their adaptability to cutting, bending, surface finishing, and recycling makes them an ideal material choice in today's engineering and design landscape.